The Original

Camshaft Belt Drive System

Smoother Than Gear Drives.

More Reliable Than Chain Drives.

Another Jesel Valvetrain Innovation

In 1982 Dan Jesel invented the Small Block Chevrolet Camshaft Belt Drive with the singular goal to make the most accurate and durable cam timing system available. Since then, our Camshaft Belt Drives have often been copied, but have never been duplicated.

Advanced Materials and Design

Constructed from the highest quality materials, Jesel Camshaft Belt Drives offer superior enhancements over conventional timing chains and gear drives. Featuring the Gates patented High Torq Drive™ reinforced belt, our system ensures smooth operation by spinning dry between a robust steel crank pulley and a hard-coated aluminum upper pulley. This setup effectively dampens crankshaft harmonics and stabilizes the valvetrain under high-performance conditions.

Enhanced Performance Features

Jesel Camshaft Belt Drives are equipped with durable Teflon® coated high vacuum cam and crank seals, meticulously designed to maintain the intense vacuum levels typical in race engines securely within the crankcase. For those looking to fine-tune performance, the cam timing can be externally adjusted by ±10° in just minutes, and our optional dual thrust cam adapter assemblies can minimize cam thrust down to as little as .001”.

Simplified Maintenance and Adaptability

Jesel Camshaft Belt Drives have also been designed to quickly perform cam swaps through the front cover. Simply remove the upper cam pulley and un-bolt the cam seal plate to save countless hours during dyno sessions without ever needing to remove the oil pan.

Wide Range of Applications

With over 65 styles and applications from OEM to aftermarket raised cam blocks, you can be certain that the same Jesel Camshaft Belt Drives used to win countless championships will also provide you with years of reliable race winning service.

Features & Benefits

Patented High Torq Drive™ Reinforced Belt: Runs dry with minimal friction, superior to timing chains or gear drives, and effectively absorbs engine harmonics.

Premium Grade 8 Hardware: Features Allen and Torx™ head designs for robust assembly and reliability.

Infinitely Adjustable Upper Pulley: Offers precise cam timing adjustments up to ±10° for optimal performance tuning.

Heat-Treated Steel Crank Pulley: Utilizes High Torq Drive™ tooth configuration for enhanced durability and performance.

Hard-Coated Billet Aluminum Upper Pulley: Employs patented High Torq Drive™ tooth configuration for maximum efficiency.

Teflon® Coated High Vacuum Seals: Ensures excellent sealing for cam and crank shafts, maintaining vacuum integrity in high-performance engines.

Versatile Accessory Options: Accommodates distributor drives, fuel pumps, or oil pumps, enhancing the functionality of the front cam setup.

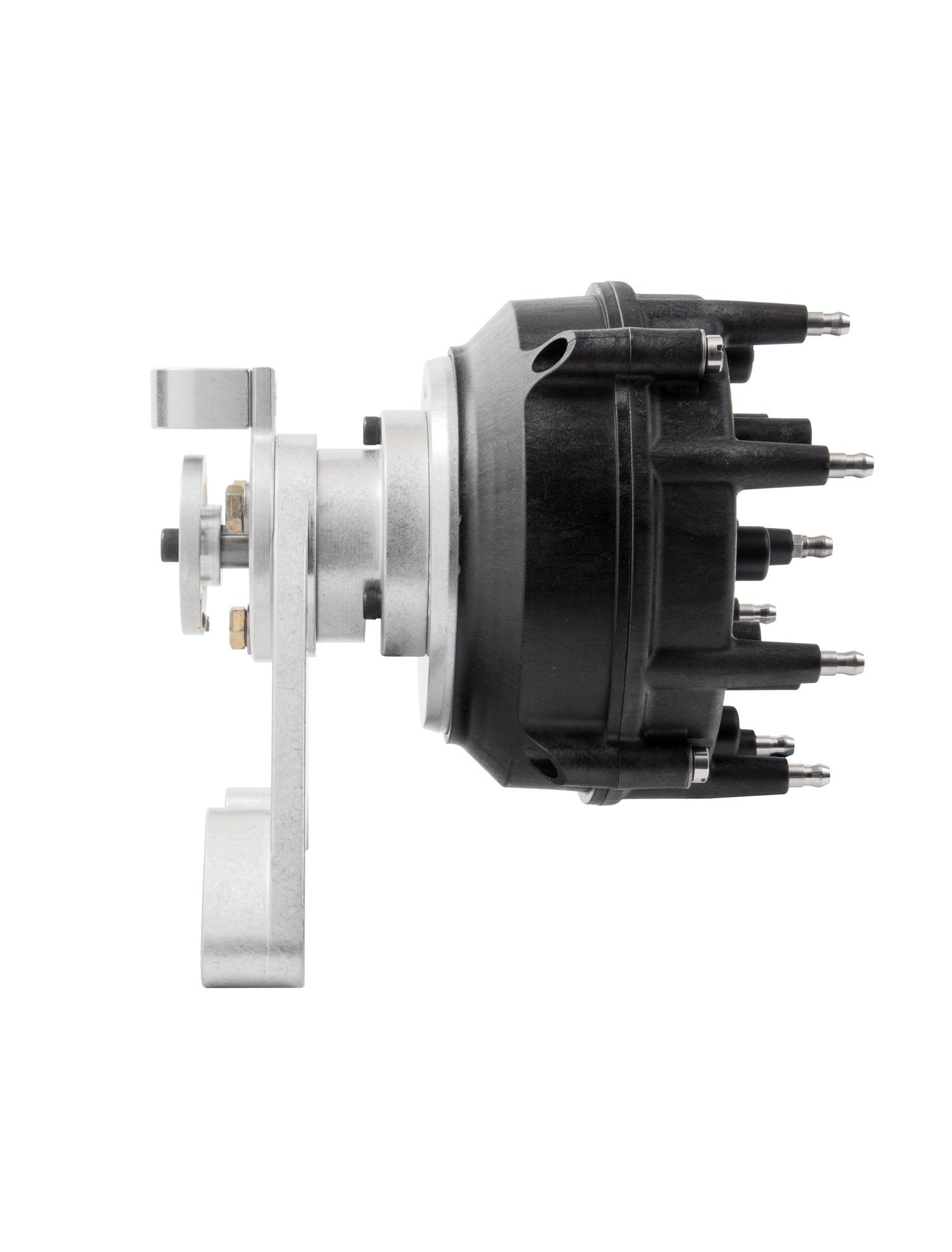

Belt Driven Distributor Drives

Eliminate Timing Inaccuracy

Distributor Drives

Jesel’s Belt Driven Distributor systems, a direct bolt-on accessory to our Camshaft Belt Drives, eliminates timing inaccuracies due to camshaft deflection and cam walk. A typical gear driven distributor running off the camshaft has the possibilty of altering the initial ignition setting at high RPM due to the camshaft twisting from torsional loads. By driving the distributor drive directly off the camshaft pulley, ignition timing stays constant and will not deviate from the initial settings. Another benefit to using our Belt Driven Distributors is the ability to set the engine back further in the chassis without worrying about firewall or windshield interference. A crank trigger firing system along with an external ignition box is required for all Belt Driven Distributor systems.

Front Drive Combos

For the engine builder planning on using a Camshaft Belt Drive as well as a Belt Driven Distributor, Jesel offers a Front Drive Combo which incorporates both units as one convenient part number. In addition to being an ordering convenience, the Front Drive Combo is easier on your budget as the units are discounted when bundled together. The combo can be ordered with either our Pro Series or Extreme Series distributors with or without the available Individual Cylinder Timing system. As with all Jesel distributor drive systems, a crank trigger type firing system as well as an external ignition box is required.

Extreme Series Distributor Drive

Introduced in 2011, Jesel’s Extreme Series Distributor Drive System is designed to handle the high cylinder pressures experienced in Pro Stock and Pro-Mod type engines. This distributor drive features the MSD® 5” Pro-Cap to ensure accurate spark delivery and to reduce spark scatter frequently experienced in high cylinder pressure applications.

Pro Series Distributor Drive

Ideal for naturally aspirated engines, this drive features a Gates PowerGrip HTD belt and uses Moroso® Ultra Series distributor components. The balanced brass rotor tip and form-staked carbon ball on the coil lug have been designed to eliminate grounding paths and cross firing.

Individual Cylinder Timing Drive

Available in either series, Jesel’s ICT timing systems provide a simple and accurate cam sync source for engines operating with an electronic fuel injection system. This drive is setup to use a 3/8-24 non-magnetic pickup (not supplied) which picks up the cam position off a rare earth magnet embedded in the external rotor. The pickup can be indexed every 60° for ideal wire routing.

Belt Drive Accessories

Dual Lip Seals

Available as a direct replacement for our standard cam and crank seals, these dual lip PTFE seals provide additional sealing for high vacuum applications. Ideal for engine builds that are trying to exceed vacuum readings over 20 in-Hg.

Zero Thrust Cam Adapters

Designed to reduce the amount of lifter-damaging camshaft endplay, these cam adapter assemblies are manufactured from through hardened tool steel and feature Torrington Needle thrust bearings. Certain block applications require machining.

Cam Timing Washer

This cam adapter washer provides a simple way to obtain a cam position signal when using electronic fuel injection. The washer can be rotated to work in conjunction with the user’s fabricated bracket and magnetic pickup.

External Dust Covers

These covers shield the Camshaft Belt Drives from unwanted debris when used in adverse conditions such as off-road and dirt tracks. Available for a limited number of applications.

Distributor Plugs

Used to replace the stock distributor when running our belt driven Distributor Drives. These plugs are available for either wet or dry sump oiling systems.

Our Belt Drive Story

In the late ‘70s Dan was looking at a belt-driven Chevy Cosworth Vega head, and came up with the idea of adapting this technology to a pushrod V8. That’s where many people would have stopped, but with Dan’s design regime of continuous improvement the end result is a belt drive system that not only drives the camshaft, it facilitates quick cam timing changes and the ability to swap cams through the front cover. It has also led to the elimination of the traditional cam-driven distributor allowing larger engine setbacks and uncompromised intake manifold design. Before the advent of the Jesel belt drive you had to drop the oil pan and remove the timing cover to swap cams or to change cam timing - a time consuming and unpleasant job at the track or shop.

People Sometimes Ask

-

A camshaft belt drive is a system that uses a reinforced belt to synchronize the rotation of the camshaft with the crankshaft, ensuring precise valve timing. Belt drives, like those from Jesel, offer greater durability and less vibration compared to chain or gear-driven systems, making them ideal for high-performance racing engines.

-

Belt drives offer several advantages over chain drives, including reduced vibrations, lower maintenance requirements, and more precise cam timing. Jesel belt drives are designed to handle the stresses of high-RPM engines while providing smooth and quiet operation compared to the noise and wear associated with chain systems.

-

Jesel camshaft belt drives provide superior accuracy in cam timing, reduced vibrations, and extended engine life. They are designed for high-performance racing applications, offering reinforced belts and precision-machined pulleys to ensure reliable operation under extreme conditions.

-

A camshaft belt drive helps to improve engine performance by maintaining precise valve timing, which is critical for optimal engine efficiency and power. Jesel belt drives are engineered to reduce slippage and wear, allowing the engine to perform consistently at high RPMs.

-

Yes, camshaft belt drives are highly reliable for racing engines, especially when using a system from Jesel. With their reinforced belts and durable pulleys, Jesel belt drives are built to withstand the extreme conditions of motorsports, ensuring long-lasting performance and minimal maintenance.

-

Yes, Jesel camshaft belt drives feature externally adjustable cam timing, allowing racers to fine-tune the engine for optimal performance. This adjustability is crucial for adapting to different track conditions and maximizing engine efficiency.

-

The lifespan of a camshaft belt drive depends on the specific application and usage conditions. Jesel belt drives are designed for durability, with reinforced belts and high-quality components that can withstand the harsh conditions of high-RPM racing engines, often lasting significantly longer than traditional chain systems.