Cartridge

ROLLER LIFTERS

Our latest roller lifter innovation

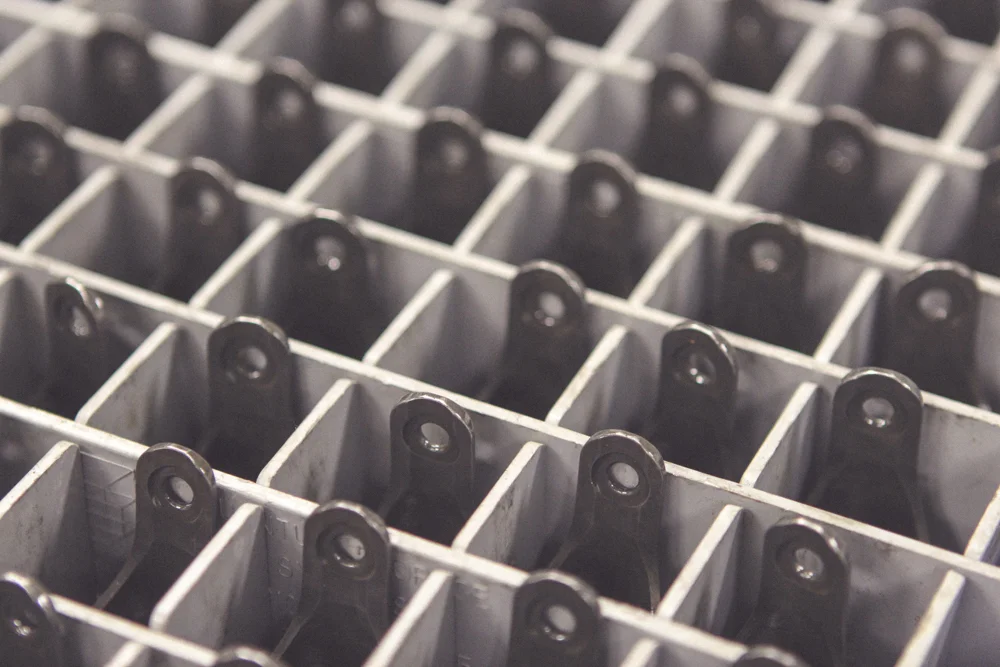

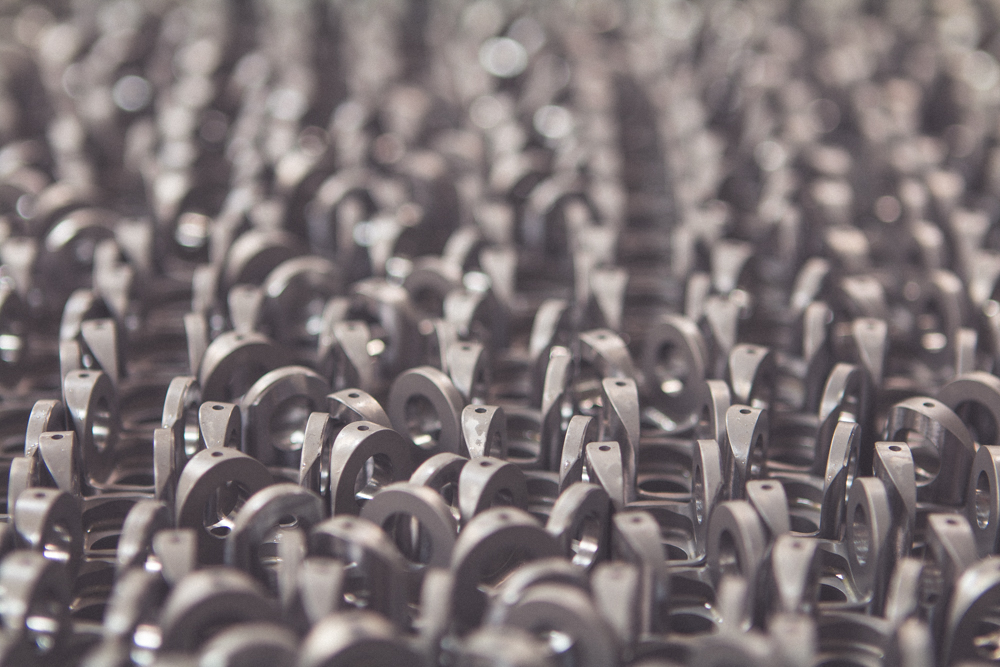

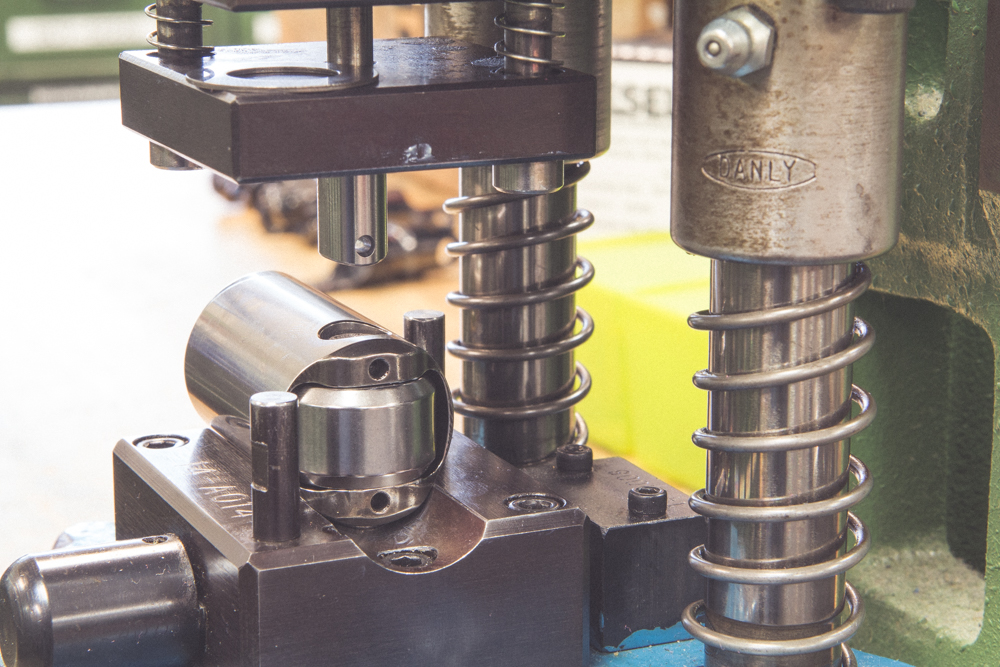

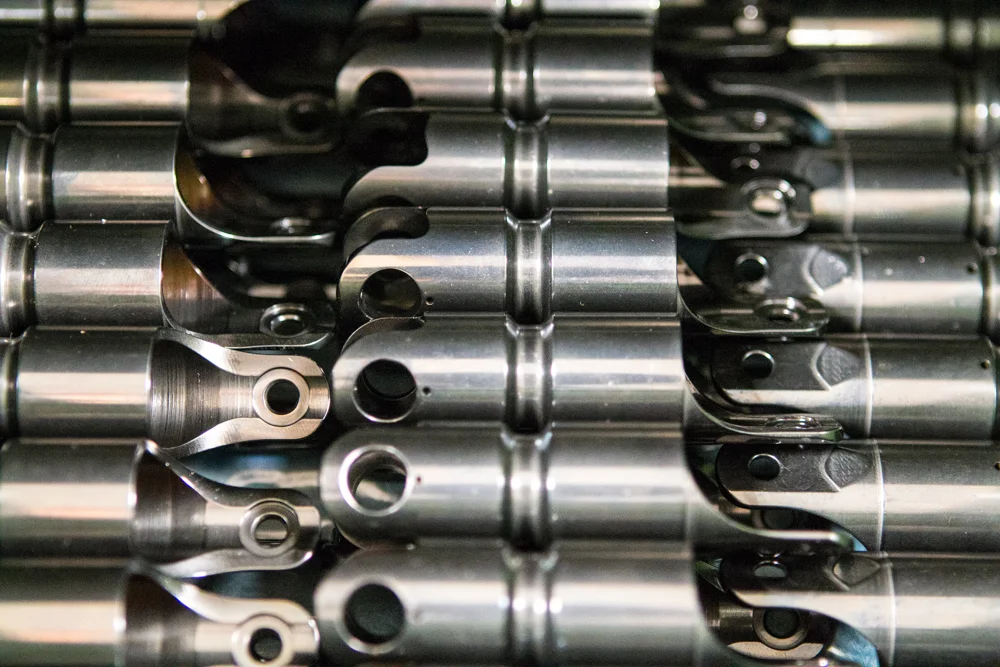

The next evolution in roller lifter technology has arrived. Designed to be used in purpose built cast iron drag race and billet aluminum blocks, these cartridge style roller guided lifters offer the engine builder options never before available.

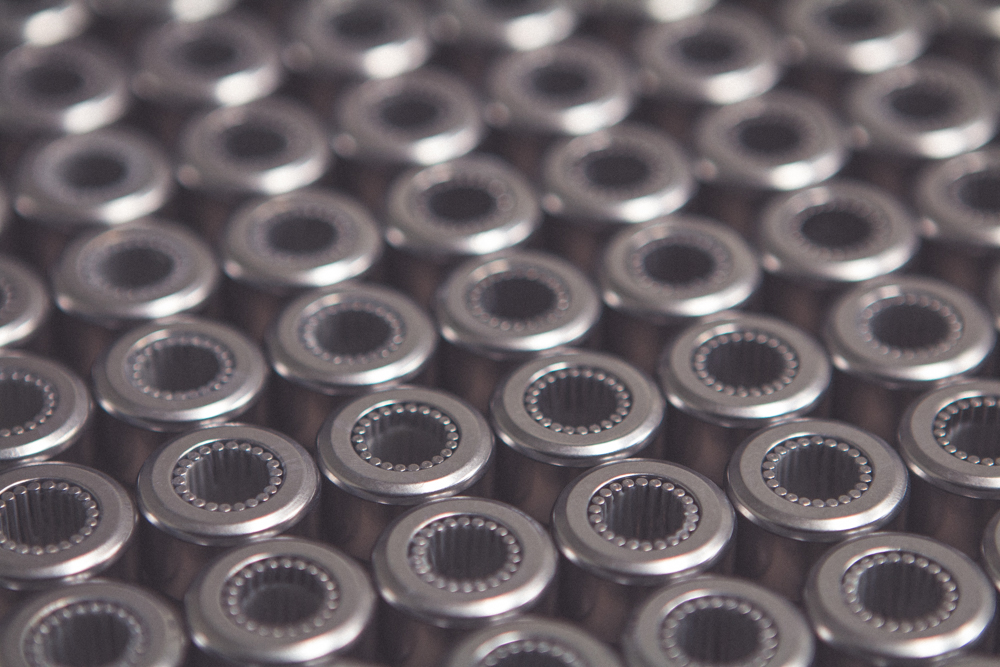

The 1.000” diameter body features a 1.220” diameter roller which is guided by channels machined into the lifter bushing. The 1.220” diameter roller not only rotates slower than a traditional .850” roller, it also reduces the pressure angle against the lifter, greatly increasing lifter life.

The bronze lifter bushing measures in at a stout 1.312” outside diameter and is secured in place by an adjustable aluminum collet that is bolted in to the lifter valley. This bushing assembly can be easily removed for block cleaning and in the event of a rare lifter failure can be removed and replaced within minutes. Ideally suited to be used in conjunction with our Clamshell Style Camshafts, these lifters will also work with conventional style camshafts.

Standard Features

DLC Coated Tool Steel 1.000” Diameter Body

On-Center or .100” Offset Pushrod Cup

Removable Bronze bushing

1.220” Diameter Roller

Offsets

Centered

.100

Specifications

The micrometer thread pitch machined into the collet and cartridge bushing allows for bushing height increments of .0125”

Oil flow should never be restricted to any Jesel Precision Roller Lifter.

Our Roller Lifter Story

Roller lifters had been around for years, being used in various applications such as radial aircraft engines, but when a few progressive engine builders started adapting them to race engines, horsepower and rpm made a huge leap forward. Cam grinders began designing cam profiles with shorter durations and higher rates of lift than a traditional solid lifter could tolerate. The result was incredible power gains especially with the typical modified O.E. style cylinder heads of the day. As valvetrain loads escalated with more lift, rocker ratio and spring pressure, the roller lifter was overtaxed and suffered frequent failures.