Premium

STUD ROCKERS

They’re Back.

First released in 1990, our Premium Stud Rockers were developed for NASCAR teams before shaft rockers were deemed legal. Reengineered and all-new, we reintroduced them in 2019 to set the standard once again. For classes where shaft rockers are not allowed such as NHRA and IHRA Stock, engine builders worldwide can now purchase rocker arms worthy of the performance and strength expected with the Jesel name.

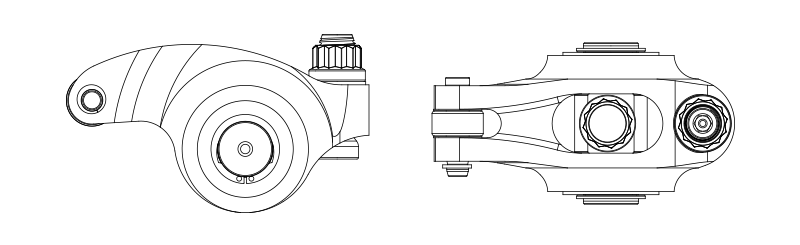

Machined from 2024 aluminum, the precision ultra-lite CNC bodies receive a shot-peened finish to help resist fatigue from stress and hot operating conditions. Dual 3/8” wide bearings with external thrust washers rotate on the precision ground tool steel trunnion to ensure stability throughout the RPM range. Jesel’s proven 3/8-24 cup style adjuster allows for precise valve lash setting and the rockers come standard with needle bearing nose rollers.

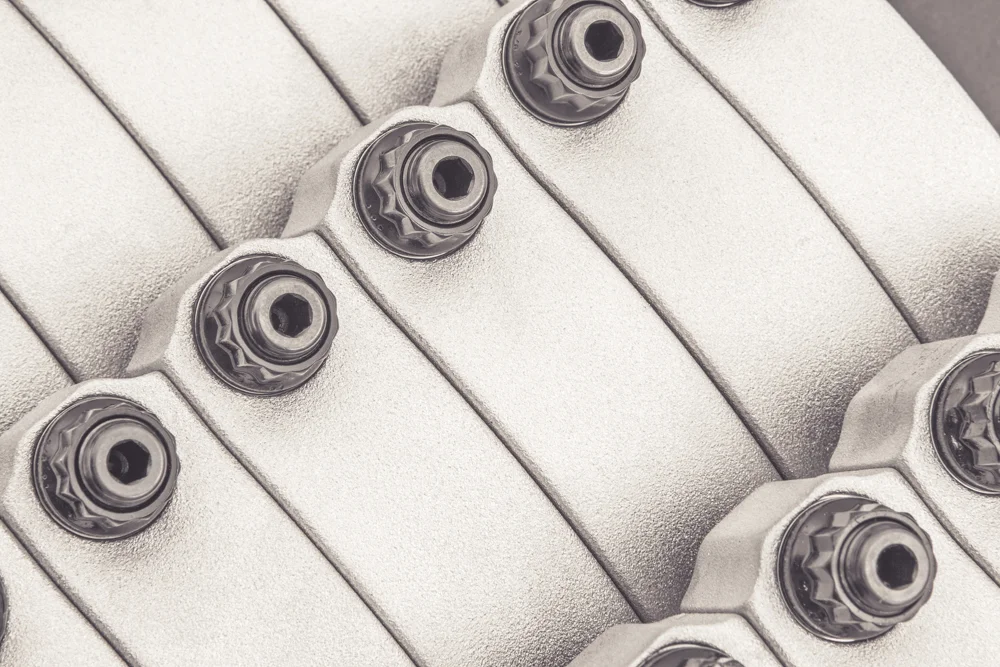

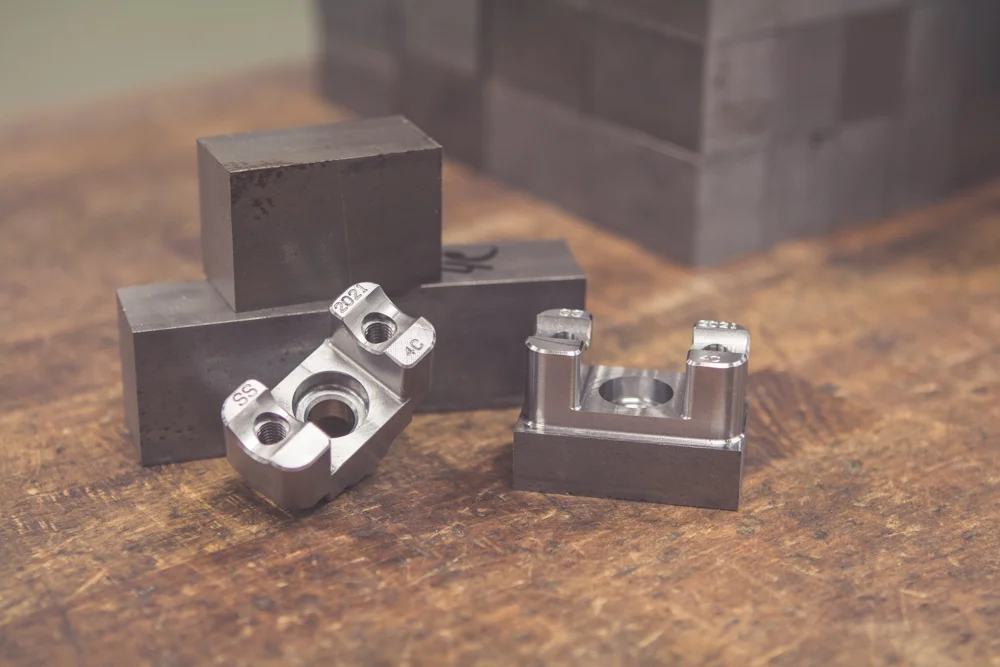

Unlike traditional stud rockers, Jesel Premium Stud rockers do not require annoying stud girdles or pushrod guide plates. The rocker pivots on a steel stanchion post which can be shimmed to adjust the rocker arm to valve tip geometry. The steel stanchion post engages into our patented retainer plate to keep the rocker arm perfectly aligned with the valve and is securely fastened to the cylinder head using a 7/16” to 3/8” stepped stud and ARP 12pt nuts.

Available for conventional 24° BB and 23° SB Chevy heads. More applications coming soon.

Jesel Premium Stud Rocker Standard Features

- 2024 Aluminum

- Shot-Peened Finish

- Dual 3/8” Wide Bearings

- External Thrust Washers

- Tool Steel Trunnion

- 3/8-24 Cup Style Adj.

- Needle Rollers

- ARP Hardware

- No stud girdles

- No pushrod guide plates

Our Rocker Story

When Chevrolet introduced its small-block V8 in 1955 one of its highly praised features was its lightweight stamped steel rocker system. With little more than a factory Duntov solid lifter cam a 7,000rpm redline was realistic. This economic valvetrain had its limits though. As long as mild seat pressures of around 100 pounds were used with low-lift hydraulic or flat tappet cams, life was good. As aftermarket cam manufacturers started grinding higher lifts, the rocker’s shortcomings began showing up. First, the rockers bottomed-out on the rocker studs because the slots were too short, then as spring pressures increased the studs pulled or broke out of the head bosses. The fixes came both from the aftermarket and GM.